Products

CIVET INDIA offers a total packaging system in terms of concept, design, sales and service.

Overview

We believes in providing their customers with exceptional after sales-services and technical support. We have an after-sales service department that caters to all our customer needs. Our dedicated engineers work around the clock to provide our customers with service and the support they deserve. All our packaging machine spare parts are manufactured at our works which is equipped with the latest machinery.

Industries We Cater To

Pharmaceutical Industry

FMCG Industry

Dairy Industry

Water Packaging Industry

Oil Packaging Industry

Food Industry

Beverage Industry

Cosmetic Industry

Product Gallery

Automatic Form Fill and Seal Machine

“CIVET-40” is a dedicated programmable logic controller based Mechanical machine that can help you to operate the machine user friendly with low maintenance.

Suitable laminated printed/unprinted rolls 50-60 kg and WMP of 200 kg. product for trial, before dispatch of the machine

- DESIGN SPEED - 60 Pouches / min

- AVERAGE O/P PER MIN - 40-45 Pouches per min

- DOSAGE - Up to 1 kg

Semi Auto Strapping Machine

Economical design of control switch, independent PCB controls feeding, tensioning and heating.

Innovatory die-cast seal blade eliminates blade distortion, short circuiting and rapid aging that are common in many

conventional strapping machines.

- Stainless steel frame is available for strapping humid products

- Instant heating in 20 seconds

- Main Gear Box & Electro Magnetic Clutch are made in Japan

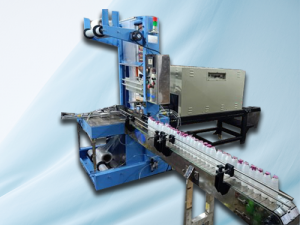

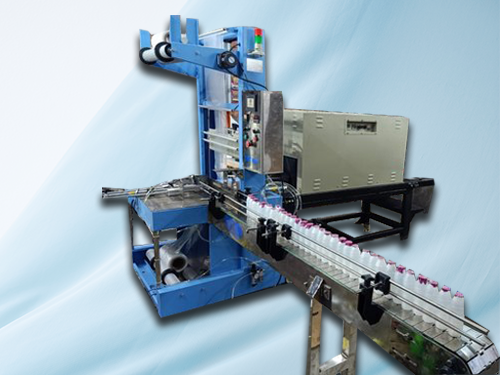

Automatic Shrink Wrapping Machine With Tunnel

Conveyor with S.S. Cross Link Mesh for Better Heating

4 KW Heaters for Hot Box 500 Watt Bottom With Out feed gravity rollers of 1000 mm & with Force cooling

- I Sealer with SMC Pneumatic Components

- Vertical Cylinder for Sealing the product in Seal Area

- Dual Motor and Heater in Hot Box

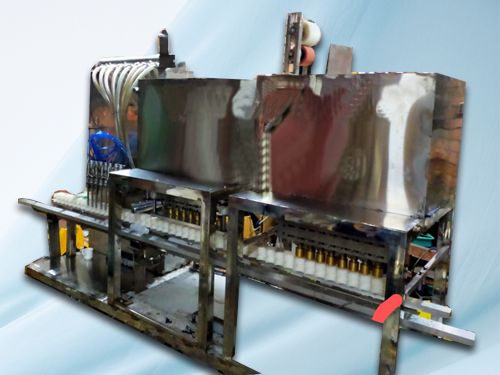

Pneumatic "L-Sealer" With PTA

Pneumatic “L-Sealer” with PTA is a CIVET india product model no is Civet LSP

Providing you the best range of pta semi automatic l-sealer and l- sealer and tunnel machines with effective & timely delivery

- DESIGN SPEED - As per your Product

- TURNNEL CONVEYOR - Silicon Pencil Chain

- BODY - Epoxy Coated

Lichi Machine Project

Highly rugged mechanical assembly results into LOW maintenance of mechanical

parts

Uninterrupted fluctuation free 3 phase 415-volt 50 Hz power supply with earthling and

neutral.

- Collar tube based

- Motorized Volume adjustment

- Strip Cutting System

Jelly Machine

Ac motor with pneumatic jaw function

Uninterrupted fluctuation free 3 phase 415-volt 50 Hz power supply with earthling and

neutral.

- AC motor operate

- Volumetric CUP filler

- Pneumatic Batch coding system

OUR CLIENTS